Slide plate type hydraulic screen changer for polymer melt filtration

ADVANTAGES

*proven technology

*leak-free model

*affordable price

*visible efficient

*easy operation

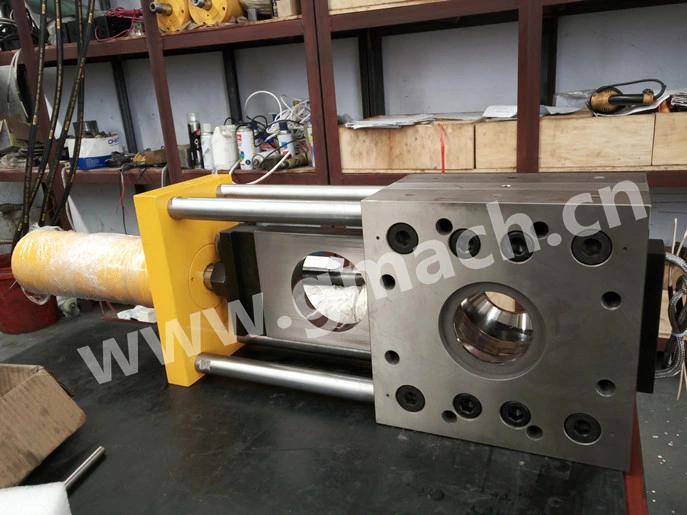

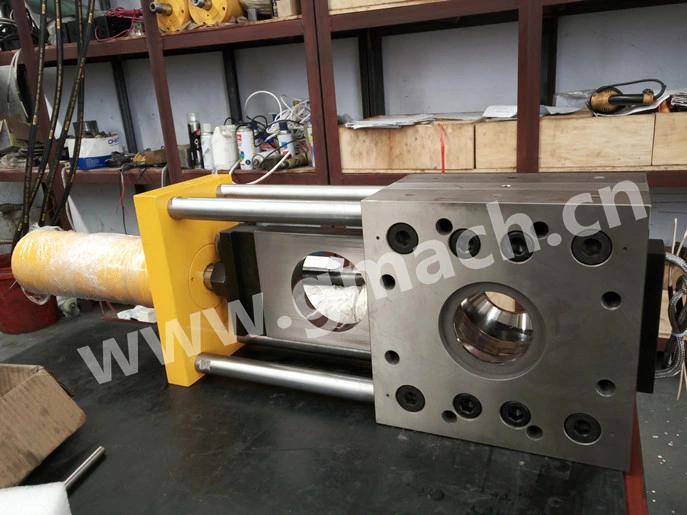

Structures of this kind of slide plate type hydraulic screen changer

The main body of the screen changer

Raw material:alloy steel(38CrMoAlA)

Surface treatment:Nitriding treatment

Depth of Nitrated Layer: 0.40-0.70mm

Nitrided hardness:950-1050Hv

Fragility of nitration: Less than grade 1

Flow channel treatment: chrome plated

Depth of chromium-plating:0.05-0.1mm

Hardness of surface after chromium-plating:HV>=950HV

Drive system:Hydraulic unit:

Hydraulic unit with accumulator

Control system

Electrical controlling system: warnning device,pressure and temperature transducer, are included

Application fields

Sheet (Foam\Strapping\Plastic cardboard)

Coating (Hot melt adhesive)

Pipe (Corrugated\Gas Pipe) and profile

Compounding (Master Batch\filler)

Wire and cable extrusion

Tubing (Medical\ Industrial\Irrigation)

Fibers (Monofilament)

Film (blow film and cast film)

Pelletizing (strands and underwater)

The packaging, this kind of slide plate type hydraulic screen changer before delivery

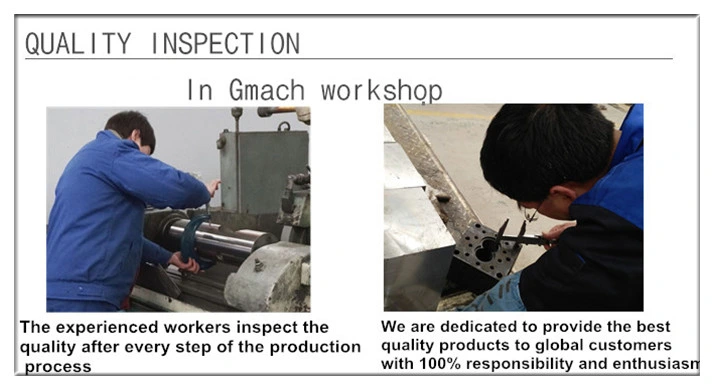

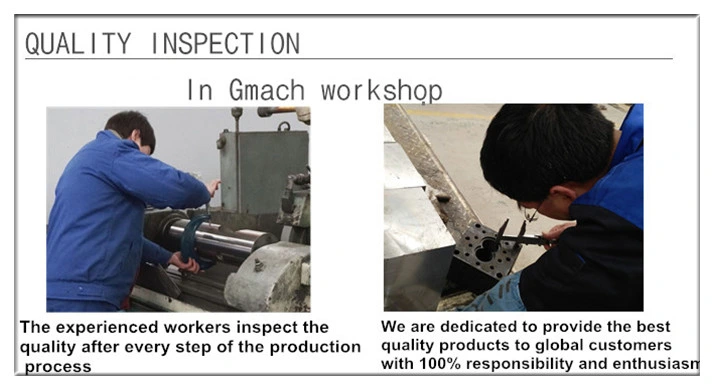

Quality inspection

We take only first class steel and check every production procedure to ensure every dimension is produced precisely. A final complete inspection will be executed before delivery.

Commissioning

We provide the operation manual for customers to gudie to install the screen changer, and at the requirement of user, salers should send technician to install and commissioning the die at site of Buyers, expenses of the trip should be borne by Buyers.

After-sales service

12 months with proper operation by user, all the spare parts shall be replaced free of charge under guarantee period, fee for transportation and packing will be borne by users.

ADVANTAGES

*proven technology

*leak-free model

*affordable price

*visible efficient

*easy operation

Structures of this kind of slide plate type hydraulic screen changer

The main body of the screen changer

Raw material:alloy steel(38CrMoAlA)

Surface treatment:Nitriding treatment

Depth of Nitrated Layer: 0.40-0.70mm

Nitrided hardness:950-1050Hv

Fragility of nitration: Less than grade 1

Flow channel treatment: chrome plated

Depth of chromium-plating:0.05-0.1mm

Hardness of surface after chromium-plating:HV>=950HV

Drive system:Hydraulic unit:

Hydraulic unit with accumulator

Control system

Electrical controlling system: warnning device,pressure and temperature transducer, are included

Application fields

Sheet (Foam\Strapping\Plastic cardboard)

Coating (Hot melt adhesive)

Pipe (Corrugated\Gas Pipe) and profile

Compounding (Master Batch\filler)

Wire and cable extrusion

Tubing (Medical\ Industrial\Irrigation)

Fibers (Monofilament)

Film (blow film and cast film)

Pelletizing (strands and underwater)

The packaging, this kind of slide plate type hydraulic screen changer before delivery

Quality inspection

We take only first class steel and check every production procedure to ensure every dimension is produced precisely. A final complete inspection will be executed before delivery.

Commissioning

We provide the operation manual for customers to gudie to install the screen changer, and at the requirement of user, salers should send technician to install and commissioning the die at site of Buyers, expenses of the trip should be borne by Buyers.

After-sales service

12 months with proper operation by user, all the spare parts shall be replaced free of charge under guarantee period, fee for transportation and packing will be borne by users.

| Type | Screen D&A | overall dimension(mm) | Heating power (KW) | Output (kg/h) | ||||

| (mm) | (CM²) | L | W | H | L1 | |||

| GM_SSP-70 | Φ70 | 38 | 200 | 170 | 240 | 820 | 3.5/5.8 | 80-200 |

| GM_SSP-100 | Φ100 | 78 | 220 | 185 | 280 | 930 | 4.5/6.8 | 150-350 |

| GM_SSP-120 | Φ120 | 113 | 260 | 205 | 320 | 1010 | 5.2/7.2 | 220-350 |

| GM_SSP-150 | Φ150 | 176 | 300 | 235 | 360 | 1140 | 6.5/8.5 | 350-800 |

| GM_SSP-180 | Φ180 | 254 | 320 | 245 | 360 | 1200 | 7.6/9.5 | 550-1250 |

| GM_SSP-200 | Φ200 | 314 | 360 | 280 | 420 | 1300 | 8.5/11 | 650-1500 |

| GM_SSP-250 | Φ250 | 490 | 450 | 300 | 430 | 1520 | 9.5/12 | 800-2500 |

| GM_SSP-300 | Φ300 | 706 | 520 | 380 | 500 | 1660 | 11.5/15.5 | 1200-3500 |

| GM_SSP-320 | Φ320 | 803 | 560 | 400 | 560 | 1700 | 13/17.5 | 1500-4000 |

| Remark: As the above specification is subject to change without prior notice | ||||||||